So what do a motorbike, a jet ski and a lawnmower have in common? They all use the 2-stroke internal combustion engine in their working. These engines are designed to be very versatile and have many applications including model airplanes, chainsaws, motorboats etc. This post aims at providing a basic understanding into the working of 2-stroke engines.

Let us now look at the basic working of the 2-Stroke Petrol Engine.

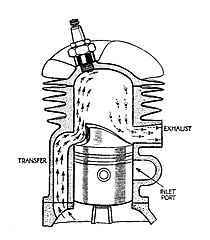

- Inlet port : The air-fuel mixture is delivered through this port into the crank case. The reed valve controls the opening and closing of this port, however, there are designs where the movement of the piston directly controls this too.

- Transfer port : The air-fuel mixture is moved from the crank case to the main body of the cylinder through this port. The opening and closing of this port is controlled by the movement of the piston in the cylinder.

- Exhaust port : The exhaust gases leave the cylinder through this port after the combustion of the air-fuel mixture. The opening and closing of the exhaust port is also controlled by the movement of the piston.

These three ports are opened and closed at different times along the cycle for operations to run smoothly.

Now, when the piston is moving upwards it compresses the air-fuel mixture in the main body of the cylinder, closing the transfer port and the exhaust port as it does so. The inlet port however is opened to let in the air-fuel mixture to be housed in the crank case at this time. At the piston’s highest point, when the air-fuel mixture has been compressed to the maximum, the spark plug ignites it releasing the potent chemical energy of the fuel.

The resulting combustion sends the piston downwards. As it moves downwards, the inlet port is closed up and the exhaust port is opened. The high pressure in the cylinder after the combustion sends the exhaust gases through this port. The piston is also compressing the air-fuel mixture in the crank case. As it moves further downward, the transfer port is opened and the piston pushes the air-fuel mixture from the crank case to the main body of the cylinder through the transfer port. The piston will then move upwards again to compress the mixture in the cylinder body starting the process all over again.

One of the major worries in the two stroke set-up is that the fresh air-fuel mixture might escape along with the exhaust gases via the exhaust port. A common change in design adopted in order to reduce this is shown below using the Deflector Piston.

Comparison with the four-stroke engine

- Elimination of valves, camshafts, pushrods and other valve timing devices from the design makes its construction much easier and weight lesser than 4-stroke engine

- The two stroke engines has a power stroke once in every revolution of the crankshaft compared to the four stroke engine which has a power stroke once every two revolutions, giving it more power.

- The two stroke engine remains functional in any orientation which is an important advantage which enables it’s use in chainsaws, model airplanes etc.

Now despite two stroke engines being lighter, more versatile, less expensive to manufacture and having more power-to-weight ratio there are some important disadvantages to be considered.

- Two stroke engines produce more pollution

- Two stroke engines do not last as long. They get worn out much sooner since they don’t have a dedicated lubrication system in place. In four stroke engines, there’s an oil pan for the crank to provide the lubrication.

- Fuel efficiency is much less for two stroke engines

1 Comment

As far as I know, in the bikes we don’t use two stroke any more. Its four stroke which is used.